Needle Processing

History of the Hiroshima needle

Hiroshima needles began 300 to 400 years ago when the technique of making karashi needles was introduced from Nagasaki. The needles were made in Hiroshima castle town were called "Nanjing Seiden Needles".

A large amount of iron was produced by the Tatara Ironworks in Hiroshima Prefecture's Yamagata-gun and transported through the Ota River. Wire was made from iron and needles were made from wire.

In Hiroshima, there is a term "Aki-Juri". These are the ten iron products that were profitable in Hiroshima. This includes needles, indicating that needles have long been nurtured as a local industry.

In the ever-changing world situation, Hiroshima's needle industry has survived by developing needle-making technology and establishing the Hiroshima needle brand while competing with competitors from Germany and England.

A large amount of iron was produced by the Tatara Ironworks in Hiroshima Prefecture's Yamagata-gun and transported through the Ota River. Wire was made from iron and needles were made from wire.

In Hiroshima, there is a term "Aki-Juri". These are the ten iron products that were profitable in Hiroshima. This includes needles, indicating that needles have long been nurtured as a local industry.

In the ever-changing world situation, Hiroshima's needle industry has survived by developing needle-making technology and establishing the Hiroshima needle brand while competing with competitors from Germany and England.

About MEIKODO and a needle

Meikodo was founded in 1949 as a 100% exporting needle company. We have been actively exporting push pins, insect pins, shirt pins, and waiting needles to North America, Asia, Europe, Latin America, and other markets around the world. The company has since expanded its market share to include Japan.

The durability of the needles manufactured in Japan is said to be the best in the world. Among them, Hiroshima Needle has the largest market share and maintains a high level of technology.

The durability of the needles manufactured in Japan is said to be the best in the world. Among them, Hiroshima Needle has the largest market share and maintains a high level of technology.

Meikodo needles are internationally recognized under the Crown Fox brand name and have supported the postwar needle industry as needle manufacturers.

Currently, we are not only making needles, but also entering the fields of wire metal processing, and molding processing. However, needle manufacturing technology is Meikodo's core competence, and other processing technologies are derived from needle manufacturing technology and developed. Based on its history, Meikodo's policy is not only to pass on needle making technology but also to develop it to a higher degree.

Currently, we are not only making needles, but also entering the fields of wire metal processing, and molding processing. However, needle manufacturing technology is Meikodo's core competence, and other processing technologies are derived from needle manufacturing technology and developed. Based on its history, Meikodo's policy is not only to pass on needle making technology but also to develop it to a higher degree.

Producing Pins

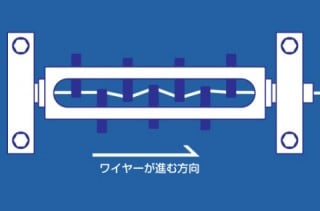

The photo on the left shows a machine that manufactures straight pins.

A single machine can perform straight line processing, header processing, cutting processing, and pointed processing.

Meikodo has been manufacturing pin machines for a long time.

The spirit that Meikodo has been connected to has been put into each of the large and small parts of the pin making machine.

A single machine can perform straight line processing, header processing, cutting processing, and pointed processing.

Meikodo has been manufacturing pin machines for a long time.

The spirit that Meikodo has been connected to has been put into each of the large and small parts of the pin making machine.

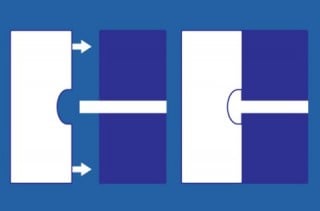

The end of the straightened wire is tapped to attach the needle head.

This process is called the cold heading (header) process.

The shape and size of the needle head is directly related to the ease of use of the needle, but is adjusted by a slight deviation of a few microns in the mechanical parts. Therefore, it is a process that requires very fine adjustment technology.

When attaching the head, the wire is cut at a certain length from the beginning. This is where the approximate size of the needle is determined.

This process is called the cold heading (header) process.

The shape and size of the needle head is directly related to the ease of use of the needle, but is adjusted by a slight deviation of a few microns in the mechanical parts. Therefore, it is a process that requires very fine adjustment technology.

When attaching the head, the wire is cut at a certain length from the beginning. This is where the approximate size of the needle is determined.

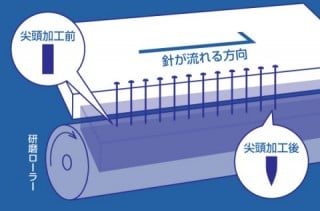

This is the process of processing the point of the needle that makes the needle exist as a needle.

This process is performed by applying a high-speed rotating grindstone to a wire cut to a certain length.

Adjust all of the angle, range and shape to be cut by how to apply the whetstone.

The tip of the needles manufactured by Meikodo is recognized as the highest quality not only in Japan but also in the handicraft market worldwide.

This process is performed by applying a high-speed rotating grindstone to a wire cut to a certain length.

Adjust all of the angle, range and shape to be cut by how to apply the whetstone.

The tip of the needles manufactured by Meikodo is recognized as the highest quality not only in Japan but also in the handicraft market worldwide.

Sharpening Tip

Pointed needles (needles without heads) are manufactured using a different method than straight pins.

Compared to straight pins, it has a higher degree of freedom in shape and can respond to various requests.

Manufactures needles for various industries, such as construction parts and medical parts, by adjusting the material, hardness, total length and needle tip shape.While some industries have high quality requirements in the micron range, the We respond to your needs with our skilled skills and know-how.

Compared to straight pins, it has a higher degree of freedom in shape and can respond to various requests.

Manufactures needles for various industries, such as construction parts and medical parts, by adjusting the material, hardness, total length and needle tip shape.While some industries have high quality requirements in the micron range, the We respond to your needs with our skilled skills and know-how.

Pointed needles are manufactured by delicate manual work labor, not by a fully automatic machine.

Since a pin-making machine cannot grip a cutting material without a head, it is manufactured by applying a cutting material to a high-speed rotating grindstone by a special mechanism that moves the pointed needles side by side.

Since a pin-making machine cannot grip a cutting material without a head, it is manufactured by applying a cutting material to a high-speed rotating grindstone by a special mechanism that moves the pointed needles side by side.